- Record: found

- Abstract: found

- Article: found

An Investigation of Surface Corrosion Behavior of Inconel 718 after Robotic Belt Grinding

Read this article at

Abstract

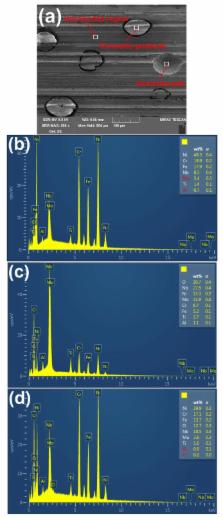

Surface corrosion resistance of nickel-based superalloys after grinding is an important consideration to ensure the service performance. In this work, robotic belt grinding is adopted because it offers controllable material processing by dynamically controlling process parameters and tool-workpiece contact state. Surface corrosion behavior of Inconel 718 after robotic belt grinding was investigated by electrochemical testing in 3.5 wt % NaCl solution at room temperature. Specimens were characterized by morphology, surface roughness and residual stress systematically. The potentiodynamic polarization curves and electrochemical impedance spectroscopy (EIS) analysis indicate the corrosion resistance of the specimen surface improves remarkably with the decrease of abrasive particle size. It can be attributed to the change of surface roughness and residual stress. The energy dispersive X-ray spectroscopy (EDS) indicates that niobium (Nb) is preferentially attacked in the corrosion process. A plausible electrochemical dissolution behavior for Inconel 718 processed by robotic belt grinding is proposed. This study is of significance for achieving desired corrosion property of work surface by optimizing grinding process parameters.

Related collections

Most cited references42

- Record: found

- Abstract: not found

- Article: not found

Effect of Grain Size on Corrosion: A Review

- Record: found

- Abstract: not found

- Article: not found

Abrasive machining of advanced aerospace alloys and composites

- Record: found

- Abstract: not found

- Article: not found