- Record: found

- Abstract: found

- Article: not found

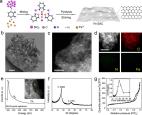

Atomically Dispersed Fe Sites Regulated by Adjacent Single Co Atoms Anchored on N‐P Co‐Doped Carbon Structures for Highly Efficient Oxygen Reduction Reaction

Abstract

Manipulating the coordination environment and electron distribution for heterogeneous catalysts at the atomic level is an effective strategy to improve electrocatalytic performance but remains challenging. Herein, atomically dispersed Fe and Co anchored on nitrogen, phosphorus co‐doped carbon hollow nanorod structures (FeCo‐NPC) are rationally designed and synthesized. The as‐prepared FeCo‐NPC catalyst exhibits significantly boosted electrocatalytic kinetics and greatly upshifts the half‐wave potential for the oxygen reduction reaction. Furthermore, when utilized as the cathode, the FeCo‐NPC catalyst also displays excellent zinc‐air battery performance. Experimental and theoretical results demonstrate that the introduction of single Co atoms with Co‐N/P coordination around isolated Fe atoms induces asymmetric electron distribution, resulting in the suitable adsorption/desorption ability for oxygen intermediates and the optimized reaction barrier, thereby improving the electrocatalytic activity.

Related collections

Most cited references51

- Record: found

- Abstract: found

- Article: not found

Understanding Catalytic Activity Trends in the Oxygen Reduction Reaction

- Record: found

- Abstract: found

- Article: not found

Engineering bunched Pt-Ni alloy nanocages for efficient oxygen reduction in practical fuel cells

- Record: found

- Abstract: found

- Article: found