- Record: found

- Abstract: found

- Article: found

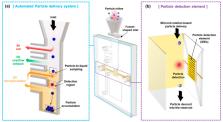

Microfluidic Airborne Metal Particle Sensor Using Oil Microcirculation for Real-Time and Continuous Monitoring of Metal Particle Emission

Read this article at

Abstract

Airborne metal particles (MPs; particle size > 10 μm) in workplaces result in a loss in production yield if not detected in time. The demand for compact and cost-efficient MP sensors to monitor airborne MP generation is increasing. However, contemporary instruments and laboratory-grade sensors exhibit certain limitations in real-time and on-site monitoring of airborne MPs. This paper presents a microfluidic MP detection chip to address these limitations. By combining the proposed system with microcirculation-based particle-to-liquid collection and a capacitive sensing method, the continuous detection of airborne MPs can be achieved. A few microfabrication processes were realized, resulting in a compact system, which can be easily replaced after contamination with a low-priced microfluidic chip. In our experiments, the frequency-dependent capacitive changes were characterized using MP (aluminum) samples (sizes ranging from 10 μm to 40 μm). Performance evaluation of the proposed system under test-bed conditions indicated that it is capable of real-time and continuous monitoring of airborne MPs (minimum size 10 μm) under an optimal frequency, with superior sensitivity and responsivity. Therefore, the proposed system can be used as an on-site MP sensor for unexpected airborne MP generation in precise manufacturing facilities where metal sources are used.

Related collections

Most cited references47

- Record: found

- Abstract: found

- Article: not found

Continuous inertial focusing, ordering, and separation of particles in microchannels.

- Record: found

- Abstract: not found

- Article: not found

A review on machinery diagnostics and prognostics implementing condition-based maintenance

- Record: found

- Abstract: not found

- Article: not found