- Record: found

- Abstract: found

- Article: found

Versatilely tuned vertical silicon nanowire arrays by cryogenic reactive ion etching as a lithium-ion battery anode

Read this article at

Abstract

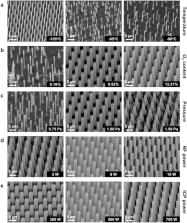

Production of high-aspect-ratio silicon (Si) nanowire-based anode for lithium ion batteries is challenging particularly in terms of controlling wire property and geometry to improve the battery performance. This report demonstrates tunable optimization of inductively coupled plasma reactive ion etching (ICP-RIE) at cryogenic temperature to fabricate vertically-aligned silicon nanowire array anodes with high verticality, controllable morphology, and good homogeneity. Three different materials [i.e., photoresist, chromium (Cr), and silicon dioxide (SiO 2)] were employed as masks during the subsequent photolithography and cryogenic ICP-RIE processes to investigate their effects on the resulting nanowire structures. Silicon nanowire arrays with a high aspect ratio of up to 22 can be achieved by tuning several etching parameters [i.e., temperature, oxygen/sulfur hexafluoride (O 2/SF 6) gas mixture ratio, chamber pressure, plasma density, and ion energy]. Higher compressive stress was revealed for longer Si wires by means of Raman spectroscopy. Moreover, an anisotropy of lattice stress was found at the top and sidewall of Si nanowire, indicating compressive and tensile stresses, respectively. From electrochemical characterization, half-cell battery integrating ICP-RIE-based silicon nanowire anode exhibits a capacity of 0.25 mAh cm −2 with 16.67% capacity fading until 20 cycles, which has to be improved for application in future energy storage devices.

Related collections

Most cited references80

- Record: found

- Abstract: found

- Article: not found

High-performance lithium battery anodes using silicon nanowires.

- Record: found

- Abstract: found

- Article: not found

Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control.

- Record: found

- Abstract: not found

- Article: not found