- Record: found

- Abstract: found

- Article: not found

Introduction to Food Irradiation and Medical Sterilization

chapter-article

There is no author summary for this article yet. Authors can add summaries to their articles on ScienceOpen to make them more accessible to a non-specialist audience.

Abstract

This chapter is comprehensive overview of sterilization and disinfectant processes

used for food-borne disease control and medical sterilization. Pathogens such as bacteria,

viruses, and endospores are described along with other infectious agents. The processes

for controlling these infectious agents in food are summarized. These processes include

not only irradiation by the two most important processes, electron beam and gamma

ray, but by other processes such as ultraviolet, microwave, and infrared radiation.

Medical sterilization and disinfectant processes are reviewed. Besides irradiative

processes, thermal processes such as steam autoclave and dry heat are reviewed. Many

liquid and gaseous chemical disinfectants are covered. The commercially important

ethylene oxide sterilization process is discussed. Dealing with bioterrorism agents

is briefly discussed. Throughout this chapter, the mechanisms, the irradiation, sterilization,

and chemical disinfectant processes used to destroy the pathogens are discussed often

in chemical detail.

This first chapter primarily focuses on the processes used to destroy microbiological

life. Microbiological life, microbes, or pathogens in food contribute to food spoilage,

disease, illness, and even death. Similarly, microbes in a health care environment

may cause disease, infections, sickness, illness, and death. The elimination, killing,

or control of microbes is therefore critically important. The processes used for microbe

control can affect the properties of materials, especially plastics. That effect is

the subject of the bulk of this book. This introductory chapter will be split up into

three parts. First will be background on the biology and types of microbes. Then the

processes used to control microbial life in the food supply are discussed. That is

followed by the control of microbes in the health care environment.

1.1

Pathogens

Sterilization processes are intended to deal with contamination of food, surfaces,

or equipment by potentially harmful life forms. These life forms are primarily bacteria,

viruses, and endospores, but could also include parasites, prions, molds, fungi, yeasts,

protozoa, etc. Organisms that cause disease are called pathogens. This section briefly

summarizes what these life forms are, which leads to a better understanding of how

sterilization processes kill or control them.

1.1.1

Bacteria

Bacteria consist of only a single cell. Bacteria fall into a category of life called

the prokaryotes. Prokaryotes' genetic material, or DNA, is not enclosed in a cellular

compartment called a nucleus as it is in eukaryotes. Not all bacteria are harmful.

However, the subject of this book implies the killing of harmful bacteria. Most people

know harmful bacteria best because of the diseases they cause. Some of these diseases

are produced when bacteria attack directly the tissues of a plant or animal. For example,

fruits and vegetables that become discolored as they are growing may be under attack

by bacteria, though discoloration may also be the result of oxidation.

Bacteria also attack cells by releasing chemicals that are poisonous to plants and

animals. Such poisons are known as toxins. As an example, Clostridium botulinum releases

a toxin that causes the most severe form of food poisoning, botulism.

Some forms of dangerous bacteria live on the human skin, but cause no harm unless

they are able to enter the body. Among these bacteria is Staphylococcus, responsible

for the potentially fatal toxic shock syndrome and gastroenteritis. The bacteria may

enter the bloodstream through a break in the skin or the digestive tract through contaminated

food. And although Escherichia coli is helpful within the digestive system, if it

is ingested it may cause cramping and diarrhea. If it enters the bloodstream, it causes

fever, hypotension, altered mental status, and possibly death.

A diagram of a typical bacterium is shown in Fig. 1.1

and a micrograph of cholera bacteria is shown in Fig. 1.2

. Bacteria can be of many other shapes, however, some of which are shown in Fig. 1.3

.

Figure 1.1

Diagram of a typical bacterium.

1

For color version of this figure, the reader is referred to the online version of

this book.

Figure 1.2

Scanning electron micrograph of cholera bacteria.

1

Figure 1.3

Common bacterial morphologies.

Bacteria are often classified as Gram positive and Gram negative. The main difference

between the two forms of bacteria is the composition and structure of the cell walls

of the two, as shown in Fig. 1.4

. Referring to the figure:

•

Peptidoglycan, also known as murein, is a polymer consisting of sugars and amino acids

that forms a mesh-like layer outside the plasma membrane of bacteria forming the cell

wall.

•

The periplasm is a space bordered by the two selective permeable biological membranes,

which are the inner plasma membrane and the outer membrane in Gram-negative bacteria.

•

There is no periplasmic space in Gram-positive bacteria because there is only one

biological membrane, but a region called inner wall zone has been observed between

the cytoplasmic membrane and the bacterial cell wall.

Figure 1.4

The structural difference of the bacterial cell walls of Gram-positive and Gram-negative

bacteria.

1

For color version of this figure, the reader is referred to the online version of

this book.

The two types of bacteria may respond differently to sterilization processes. Sterilization

processes that kill bacteria usually do so by:

•

Causing damage to the physical structure, particularly rupture of the cell walls

•

Altering the membrane permeability

•

Damaging the proteins within the cells

•

Damaging the nucleic acids in the DNA or RNA.

1.1.2

Viruses

A virus is a small infectious agent that can replicate only inside the living cells

of organisms. They are too small to be seen with a light microscope. Viruses are not

plants, animals, or bacteria, but they are more like parasites. They are parasites

because without a host cell, they cannot carry out their life-sustaining functions

or reproduce. Although they may seem like living organisms because of their reproductive

abilities, viruses are not living.

The average virus is about one-hundredth the size of the average bacterium. All viruses

contain nucleic acid, either DNA or RNA (but not both), and a protein coat, which

encases the nucleic acid. Viruses come in a wide diversity of shapes and sizes called

morphologies.

2

Viruses are inactive when outside of a living cell, but their nucleic acid once entering

the cell can take over the cells' activities, which is primarily to reproduce and

break out of the cell to infect other cells. Figure 1.5

shows electron micrographs of two different viruses. The micrograph of the virus on

the right side clearly shows the DNA and cell wall structure.

Figure 1.5

Electron micrographs of two viruses, a bacteriophage on the left and an influenza

virus on the right.

3

For color version of this figure, the reader is referred to the online version of

this book.

1.1.3

Endospores

An endospore is a dormant, tough, and temporarily nonreproductive structure produced

by certain bacteria. It is a stripped-down, dormant form to which the bacterium can

reduce itself when conditions are not right for the bacterium to thrive. It is very

resistant to harsh environments and can remain viable for very long periods of time,

only to spring back to life when conditions are right.

The structure and a micrograph of an endospore are shown in Fig. 1.6

. The endospore consists of the bacterium's DNA and part of its cytoplasm, surrounded

by a very tough outer coating. The coating consists of multiple layers. The outermost

layer is the exosporium, which is a thin protein covering. The next layer is the spore

coat which is comprised of spore-specific proteins. An outer membrane surrounds the

cortex. The cortex is composed of peptidoglycan containing some dipicolinc acid and

calcium ions that cross-link. This creates a highly impenetrable layer that provides

the heat resistance properties of the endospore. The core contains the cell wall and

cytoplasmic membrane, nuclear material, some ribosomes, RNA molecules, and enzymes.

The core contains much less water than the bacterial cell.

Figure 1.6

Structure of an endospore on the left and a micrograph of anthrax spores on the right.

For color version of this figure, the reader is referred to the online version of

this book.

Endospores are highly resistant to hostile physical and chemical conditions. They

allow a bacterium to survive suboptimal environmental conditions. Because these spores

are resistant to heat, radiation, disinfectants, and desiccation, they are difficult

to eliminate (but not impossible) from medical and pharmaceutical materials and are

a frequent cause of contamination.

1.1.4

Other Infectious Agents

There are other infectious agents may require control. These are listed in the next

few sections.

1.1.4.1

Prions

A prion is an infectious agent, rather than a life form, composed of protein in a

misfolded form. The group of fatal neurodegenerative diseases are called transmissible

spongiform encephalopathies that include bovine spongiform encephalopathy (also known

as “mad cow disease”) in cattle and Creutzfeldt–Jakob disease (CJD) in humans. They

occur in animals (dogs, cows, and primates) as well as humans and are rapidly fatal

once symptoms develop. Prions propagate by transmitting a misfolded protein state.

When a prion enters a healthy organism, it induces existing, properly folded proteins

to convert into the disease-associated, prion form. It acts as a template to guide

the misfolding of more protein into prion form. This altered structure is extremely

stable and accumulates in infected tissue, causing tissue damage and cell death. CJD

poses a unique infection prevention problem because prions, which are protein-containing

infectious agents, can survive many common sterilization processes.

1.1.4.2

Helminthes

A parasitical organism is a life form that lives off the host. Helminthes or parasitic

worms are a division of eukaryotic parasites. They are worm-like organisms that live

and feed off living hosts, receiving nourishment and protection while disrupting their

hosts' nutrient absorption, causing weakness and disease. Those that live inside the

digestive tract are called intestinal parasites. Figure 1.7

shows one of these parasitic worms. They can live inside humans as well as other animals.

The helminthes not only reside in the digestive tract. They may reside in other tissues.

Trichinosis is a well-known example. Trichinosis is infection with the microscopic

roundworm Trichinella spiralis. A micrograph of the trichinosis parasites in muscle

tissue is shown in Fig. 1.8

.

Figure 1.7

Micrograph of hookworm parasites on intestinal wall.

1

For color version of this figure, the reader is referred to the online version of

this book.

Figure 1.8

Micrograph of trichinosis parasites in muscle tissue.

1

For color version of this figure, the reader is referred to the online version of

this book.

1.1.4.3

Fungi: Molds and Yeasts

A fungus is a eukaryotic organism. Fungal cells have cell walls that contain chitin,

unlike the cell walls of plants, which contain cellulose. Chitin is a polymer of N-acetylglucosamine.

Molds are fungi that grow in the form of multicellular filaments called hyphae, such

as shown in Fig. 1.9

, which shows other labeled features. Microscopic fungi that grow as single cells

are called yeasts. Figure 1.10

shows a micrograph of a yeast.

Figure 1.9

Micrograph of Penicillium showing (1) hypha, (2) conidiophore, (3) philalide, (4)

conidia, and (5) septa.

1

For color version of this figure, the reader is referred to the online version of

this book.

Figure 1.10

Micrograph of yeast species Saccharomyces cerevisiae.

1

Some molds cause disease or food spoilage. Many fungi produce biologically active

compounds, several of which are toxic to animals or plants and are therefore called

mycotoxins. Of particular relevance to humans are mycotoxins produced by molds causing

food spoilage. Inhaled fungal spores are a well-known cause of allergy and asthma.

Some human diseases caused by fungi include:

•

Aspergillosis

•

Candidiasis

•

Coccidioidomycosis

•

Histoplasmosis

•

Mucormycosis

•

Opportunistic pneumonia

•

Thrush.

As such, there is a need to control or kill fungi in the food-processing and in the

medical environment.

1.1.4.4

Protozoans

Protozoa are unicellular eukaryotes, meaning that they have characteristic organelles.

They are relatively large and some are visible with the naked eye. Not all protozoa

are of concern to public health.

Those that are pathogens include:

•

Toxoplasma

•

Isospora

•

Cryptosporidium

•

Cyclospora

•

Sarcocystis

•

Plasmodium

•

Giardia

•

Cryptobia species

•

Enterocytozoon bieneusi

•

Pleistophora species.

However, there have been rare infections by amoeba, Naegleria fowleri, in the news

recently. The news media have called these “brain-eating amoeba.” For the infections

in the news, the amoeba entered the brain after contaminated warm water entered the

nose, though there were also cases caused by head trauma.

1.1.5

Biofilm

A biofilm is an aggregate of microorganisms in which cells adhere to each other on

a surface. Dental plaque, the slimy coating that fouls pipes and tanks, and algal

mats on bodies of water are examples of biofilms. Biofilms can form on solid or liquid

surfaces as well as on soft tissue in living organisms. They are typically resistant

to conventional methods of disinfection. These adherent cells in a biofilm are frequently

embedded within a self-produced matrix of extracellular polymeric substance (EPS).

Biofilm EPS, which is also referred to as slime (although not everything described

as slime is a biofilm), is a polymeric conglomeration generally composed of extracellular

DNA, proteins, and polysaccharides. Biofilms may form on living or nonliving surfaces

and can be prevalent in natural, industrial, and hospital settings.

Biofilms have been found to be involved in a wide variety of microbial infections

in the body. Biofilms have been implicated in common problems such as urinary tract

infections, catheter infections, middle-ear infections, formation of dental plaque,

gingivitis, and coating contact lenses. Though less common but more lethal, biofilms

have also been implicated in health problems such as endocarditis, infections in cystic

fibrosis, and infections of permanent implanted devices such as joint prostheses and

heart valves.

1.2

Food-Borne Disease Control

Concern over food-borne diseases is high. These are the illnesses contracted from

eating contaminated foods or beverages. These illnesses include food-borne intoxications

and infections and are often incorrectly referred to as food poisoning. There are

more than 250 different food-borne diseases and they are caused by viruses, bacteria,

parasites, toxins, metals, and prions. According to the US Center for Disease Control

(CDC), 31 pathogens are known to cause 20% of the food-borne illnesses, with 80% being

caused by unknown agents. Studies by the CDC in 2010 estimated that food-borne diseases

each year cause roughly one in six Americans (or 48 million people) to get sick; 128,000

are hospitalized, and 3000 die of food-borne diseases. Symptoms of food-borne illness

range from mild gastroenteritis to life-threatening neurologic, hepatic, and renal

syndromes. Some of these illnesses are well known and include: botulism, brucellosis,

Campylobacter enteritis, E. coli, hepatitis, listeriosis, salmonellosis, shigellosis,

toxoplasmosis, viral gastroenteritis, teniasis, and trichinosis. Food-borne diseases

pose a widespread threat to human health and they may lead to reduced economic productivity.

Economic losses associated with such food-borne diseases are high estimated between

US $6500 million and $33,000 million.

Eight known pathogens account for the vast majority of illnesses, hospitalizations,

and deaths. Table 1.1, Table 1.2, Table 1.3

list the top five pathogens causing illness, hospitalization, and death.

Table 1.1

Top Five Pathogens Contributing to Domestically Acquired Food-Borne Illnesses

4

Pathogen

Estimated Number of Illnesses

90% Credible Interval

% of Total

Norovirus

5,461,731

3,227,078–8,309,480

58

Salmonella, nontyphoidal

1,027,561

644,786–1,679,667

11

Clostridium perfringens

965,958

192,316–2,483,309

10

Campylobacter species

845,024

337,031–1,611,083

9

Staphylococcus aureus

241,148

72,341–529,417

3

Subtotal

91

Table 1.2

Top Five Pathogens Contributing to Domestically Acquired Food-Borne Illnesses Resulting

in Hospitalization

4

Pathogen

Estimated Number of Hospitalizations

90% Credible Interval

% of Total

Salmonella, nontyphoidal

19,336

8545–37,490

35

Norovirus

14,663

8097–23,323

26

Campylobacter species

8463

4300–15,227

15

Toxoplasma gondii

4428

3060–7146

8

Escherichia coli (STEC) O157

2138

549–4614

4

Subtotal

88

Table 1.3

Top Five Pathogens Contributing to Domestically Acquired Food-Borne Illnesses Resulting

in Death

4

Pathogen

Estimated Number of Deaths

90% Credible Interval

% of Total

Salmonella, nontyphoidal

378

0–1011

28

Toxoplasma gondii

327

200–482

24

Listeria monocytogenes

255

0–733

19

Norovirus

149

84–237

11

Campylobacter species

76

0–332

6

Subtotal

88

Beyond the illnesses, there is the economic cost of high food losses from infestation,

contamination, and spoilage caused by insects and bacteria. Killing the microbes and

insects that cause these losses by food irradiation can help reduce these losses.

Even though there have been ways to preserve foods for centuries, if not millenia,

the cause was not understood until the mid-nineteenth century.

As mentioned in the introduction of this chapter, the killing of microbes in food

is a large-scale or bulk process. Heat is one of the best ways to kill microbes, but

it is not often desirable to cook the foods prior to sale. The irradiation processes

using gamma, electron beam (or beta), infrared (IR), and microwave are used. However,

the problem of food preservation has long been accepted and over time have ways have

been developed to preserve food. The history of food preservation is interesting.

1.2.1

The History of Food Preservation

Many primitive and tedious methods of food preservation have been used. Some of these

were developed thousands of years ago and are still used today. These include:

•

Drying – Drying was and still is used to preserve fruit, vegetables, meats, and fish.

Foods can be dried in the sun (as the ancients did), in an oven or in a food dehydrator

by using the right combination of warm temperatures, low humidity, and air current.

Drying removes the moisture from the food, so bacteria, yeast, and mold that need

water cannot grow and spoil the food.

•

Chemical pickling – Food for pickling is placed in an edible liquid that inhibits

or kills bacteria and other microorganisms. There are many pickling agents including

brine (high in salt), vinegar, alcohol, and vegetable oil (particularly olive oil).

Many chemical pickling processes also involve heating or boiling so that the food

being preserved becomes saturated with the pickling agent. In fermentation pickling,

the food itself produces the preservation agent, typically by a process that produces

lactic acid. This is commonly used to preserve vegetables.

•

Salting – Salting has been used extensively for pork, beef, and fish. The origins

of salt-preserving food can be traced back to at least ancient Egypt, where they used

salt as part of the embalming process, as well as in food preservation.

•

Sugaring – Sugaring is used to preserve fruits for the winter, producing jams and

jellies. Sugaring is the process of desiccating a food by first dehydrating it and

then packing it with pure sugar. The sugar can be crystalline table or raw sugar,

or it can be a high-sugar-density liquid such as honey, syrup, or molasses.

•

“Cold storage” – Root cellars, ground burial, and iceboxes were cold storage methods

used before the development of refrigeration.

•

Smoking – Smoking is the exposure of cured meat and fish products to smoke for the

purposes of preserving them and increasing their palatability by adding flavor and

imparting color. The drying action of the smoke tends to preserve the meat, though

many of the chemical species present in wood smoke (e.g. formaldehyde and certain

alcohols) are natural preservatives as well. Smoking is one of the oldest of food

preservation methods.

•

Canning – Canning is a method of preserving food in which the food contents are processed

and sealed in an airtight container. Canning was developed around 1810 by Nicolas

Appert in Paris. It revolutionized food preservation.

•

Blanching – Also known as parboiling, blanching is the method by which foods are partially

cooked as a way to preserve their color, texture, and flavor.

1.2.2

The History of Food Irradiation

Antoine-Henri Becquerel (1852–1908) is known for his discovery of radioactivity in

1895, for which he received the 1903 Nobel Prize for Physics jointly with Marie Curie

and Pierre Curie. X-rays were also discovered in 1895 by W.K. Roentgen. Ionizing radiation

was found to be lethal to living organisms soon after these discoveries. The idea

of using ionizing radiation in food preservation almost immediately followed. The

suggestion to use ionizing energy to destroy pathogenic and spoilage microorganisms

in food was published in a German medical journal the same year. However, the cost

and quantity of this radiation inhibited commercial development until much, much later.

The basic history of food irradiation follows

5

:

•

1905 – Scientists receive patents for a food preservative process that uses ionizing

radiation to kill bacteria in food.

•

1921 – US patent is granted for a process to kill Trichinella spiral in meat by using

X-ray technology.

•

1953–1980 – The US Government forms the National Food Irradiation Program. Under this

program, the US Army and the Atomic Energy Commission sponsor many research projects

on food irradiation. The US Army's interest is feeding soldiers during wartime.

•

1958 – The Food, Drug, and Cosmetic Act is amended and defines sources of radiation

intended for use in processing food as a new food additive. The Act is administered

by Food and Drug Administration (FDA).

•

1963 – FDA approves irradiation to control insects in wheat and flour.

•

1964 – FDA approves irradiation to inhibit sprouting in white potatoes.

•

1964–1968 – The US Army and the Atomic Energy Commission petition FDA to approve the

irradiation of several packaging materials.

•

1966 – The US Army and US Department of Agriculture (USDA) petition FDA to approve

the irradiation of ham.

•

1971 – FDA approves the irradiation of several packaging materials based in the 1964–68

petitions by the US Army and the Atomic Energy Commission.

•

1976 – The US Army contracts with commercial companies to study the wholesomeness

of irradiated ham, pork, and chicken.

•

1980 – USDA inherits the US Army's food irradiation program.

•

1985 – FDA approves irradiation at specific doses to control Trichinella spiral is

in pork. FDA approves irradiation at specific doses to delay maturation, inhibit growth,

and disinfect foods, including vegetables and spices. The Federal Meat Inspection

Act is amended to permit gamma radiation to control Trichinella spiral is in fresh

or previously frozen pork. Law is administered by USDA.

•

1990 – FDA approves irradiation for poultry to control Salmonella and other food-borne

bacteria.

•

1992 – USDA approves irradiation for poultry to control Salmonella and other food-borne

bacteria.

•

1997 – FDA's regulations are amended to permit ionizing radiation to treat refrigerated

or frozen uncooked meat, meat by-products, and certain food products to control food-borne

pathogens and to extend shelf life.

•

2000 – USDA's regulations are amended to allow the irradiation of refrigerated and

frozen uncooked meat, meat by-products, and certain other meat food products to reduce

the levels of food-borne pathogens and to extend shelf life. FDA's regulations are

amended to permit the irradiation of fresh shell eggs to control Salmonella.

1.2.3

Dosage Measures of Radiation

The radiation dose for food irradiation and sterilization generally is measured using

the conventional unit rad or the SI unit gray (Gy). The rad, which stands for radiation

absorbed dose, was the conventional unit of measurement, but it has recently been

replaced by the Gy; 1 Gy is equal to 100 rad. The prefix kilo (k), for 1000×, is commonly

used with the gray unit, kGy. Mega (M) for 1,000,000× is often used with the rad unit

(Mrad). This is summarized in Table 1.4

.

Table 1.4

Conversion of Common Rad and Gray Units of Irradiation

The Rad (rad) is Replaced by the Gray (Gy)

The Gray (Gy) Replaces the Rad (rad)

1 megarad (Mrad) = 10 kilogray (kGy)

1 kilogray (kGy) = 0.1 (Mrad)

1 kilorad (krad) = 10 gray (Gy)

1 gray (Gy) = 100 rad (rad)

1 rad (rad) = 10 milligray (mGy)

1 milligray (mGy) = 100 millirad (mrad)

1 millirad (mrad) = 10 microgray (μGy)

1 microgray (μGy) = 100 microrad (μrad)

1 microrad (μrad) = 10 nanogray (nGy)

1 nanogray (nGy) = 100 nanorad (nrad)

There are other radiation measures: Curie (Ci), Becquerel (Bq), Roentgen (R), Coulomb/kg

(C/kg), The rem (rem), and Sievert (Sv). However, these are used for other purposes.

1.2.4

Electron Beam Irradiator

Electron beam irradiation is sometimes referred to as beta irradiation. Beta particles

are high-energy, high-speed electrons or positrons emitted by certain types of radioactive

nuclei such as potassium-40. Beta particles are subatomic particles ejected from the

nucleus of some radioactive atoms. They are equivalent to electrons. The difference

is that beta particles originate in the nucleus and electrons originate outside the

nucleus.

Electron beam radiation breaks the DNA or damages other critical molecules in bacteria,

either killing them or preventing them from reproducing.

The procedure for electron beam irradiation is relatively simple. In practice, a continuous

process is used to improve the economics of the process. The source of electron beams

is an “accelerator.” The accelerator converts electricity through a tungsten filament

source.

Accelerators generate and accelerate electrons and direct them toward the food product

needing irradiation. An accelerator (see Fig. 1.11

) consists of four major systems:

1.

Voltage generator

2.

Acceleration tube and electron gun

3.

Scan chamber and scan horn

4.

A control system.

Figure 1.11

Diagram of an electron beam generator.

Each segment plays a key role and is briefly described. Low voltage power, typically

three-phase, 440 V AC, is converted to high-frequency (100 kHz) radio frequency (RF)

power by an oscillator. A number of rectifiers in series along with an RF resonant

transformer convert the RF power into ultra high voltage (2–5 MM V) direct current

(DC) power. The DC voltage is sent to the acceleration tube. This tube is a hollow

vacuum cylinder made from glass and metal. Glass rings are positioned as insulation

rings in between metal rings, called dynodes. An electron gun is positioned at the

entry point of the tube. A tungsten filament is the source of electrons that are emitted

by heating the filament. The continuous electron stream is accelerated through a vacuum

tube, supplying a high-energy beam with a diameter of 2–3 cm. The accelerated beam

is transmitted through an oscillating magnetic field with a frequency of 200 Hz that

converts the tight beam cone into a wide curtain of electrons with a width of 1–2.5 m.

A thin titanium window acts as a window or a filter before the beam reaches the food

to be irradiated. A control system monitors all the functions of the various systems

of accelerator to insure proper and consistent operation.

An accelerator operates based on a number of factors including voltage (electron energy),

beam current, and beam power. Because electrons have mass, they can only penetrate

about 1.5 inches (3.8 cm) into a typical food product or about 3.5 inches (8.9 cm)

if the food product is irradiated on both sides. Electrons also have an electric charge.

This charge allows the stream of accelerated electrons to be scanned by magnets to

track across the product. A commercial food electron beam irradiator accelerates the

electrons to an energy of up to 10,000,000 electron volts [10 million electron volts

(MeV)]. Electron beam irradiators typically use massive concrete, steel, or lead shielding.

Electron beam accelerators can be turned on and off. Safety interlocks ensure that

a person cannot enter the radiation chamber where the food is being irradiated when

the accelerator is “on.” Product is usually passed through the scanned “beam” on roller-type

conveyors as shown in Fig. 1.12

. A picture of the electron beam scan horn and conveyor system in the irradiation

area is shown in Fig. 1.13

.

Figure 1.12

A schematic of an electron beam irradiation facility with two-side irradiation for

food irradiation. For color version of this figure, the reader is referred to the

online version of this book.

Figure 1.13

Scan horn and conveyor system of an Iotron IMPELA® 10/50 Linear Electron Accelerator

Installed at Iotron Industries USA Inc., Columbia City, Indiana (photo courtesy of

Iotron Industries Canada/USA Inc.). For color version of this figure, the reader is

referred to the online version of this book.

1.2.5

Gamma Irradiator

Gamma radiation, signified by the Greek letter γ, is one of the three types of natural

radioactivity. Gamma rays are electromagnetic radiation, like X-rays, except even

more energetic. They have enough energy to ionize matter and can damage or destroy

living cells, which is of course why they are useful for sterilization. The source

of gamma rays in a gamma irradiator is Cobalt-60. Cobalt-60 radioactively beta decays

to Nickel-60 and emits two gamma rays with energies of 1.17 and 1.33 MeV.

6

Cobalt-60 is not found in nature. It is a synthetic radioactive isotope made by neutron

activation of Cobalt-59. Cobalt-60 is produced off site in nuclear reactors and transported

in special shipping containers (casks) to the sterilization facility. Cobalt-60 is

a solid radioactive metal molded into a cylindrical slug as shown in Fig. 1.14

. The slugs are loaded into “sealed source” pencils made of stainless steel. The stainless

steel sealed source contains the “radioactive” Cobalt-60, but allows the gamma photons

(radiation) to pass through the steel. The pencils are arranged into flat panel arrays.

Cobalt-60 continuously emits radiation and cannot be turned “off.” The arrays are

stored in a deep water pool, which prevents gamma radiation from escaping. The shielding

water does not become radioactive.

Figure 1.14

Cobalt-60 slugs are arranged into source racks [images/photos courtesy of Nordion

(Canada) Inc.]. For color version of this figure, the reader is referred to the online

version of this book.

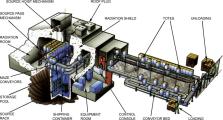

Large-scale gamma irradiators come in two configurations. In one configuration, the

Cobalt arrays are hoisted out of the water into a radiation chamber that typically

has shields made out of massive concrete or steel. This is shown in Fig. 1.15

. The concrete walls are typically 2-feet thick or more. When the irradiators are

out of the protective storage pool, all workers are outside the thick walls. Hanging

carriers, totes, or roller conveyors are typically employed to move the product through

the chamber for irradiation. A typical product container can be 60 cm × 50 cm × 150 cm,

and some irradiators are designed to irradiate entire pallets of product measuring

120 cm × 100 cm × 150 cm. Because Cobalt-60 photons have no mass, they can penetrate

more than 24 inches (60 cm) of food product if irradiated on both sides.

Figure 1.15

A schematic of a gamma irradiation facility [images/photos courtesy of Nordion (Canada)

Inc.]. For color version of this figure, the reader is referred to the online version

of this book.

In the second configuration, unlike a radiation chamber irradiator, an underwater

irradiator stores the Cobalt-60 permanently at the bottom of a pool of water. Instead

of raising the Cobalt-60 into a shielded chamber, the product, placed in water-free

containers, is lowered to the bottom of the pool adjacent to the Cobalt-60 to receive

a dose of radiation. No above-ground shielding or radiation chamber is present. Typically,

the product is loaded into water-free containers and the containers are lowered/raised

using a hoist mechanism.

1.2.6

X-Ray Irradiator

X-rays are photons and have similar properties to gamma rays emitted by Cobalt-60.

However, X-rays are generated by using an electron beam accelerator and converting

the electron beam (up to 7.5 MeV) to photons by accelerating the electrons into a

high-density material such as tungsten, steel, or tantalum. The sudden deceleration

of the electrons generates X-rays and waste heat. The shielding and product conveyance

are similar to that of a chamber-type gamma irradiator (Fig. 1.15). The advantages

of X-rays over electron beams are that they have good product penetration (over 24

inches or 60 cm of food product if irradiated on both sides). The advantage of X-rays

over gamma irradiators is that they do not require a shielding storage pool. However,

there is a substantial loss of energy during the conversion process. Thus, it suffers

a severe cost disadvantage when compared to other types of irradiators for the same

product volume throughput. For food irradiation, X-ray machines can have a maximum

energy of 5 MeV.

1.2.7

Ultraviolet Germicidal Irradiation

Ultraviolet (UV) is the part of the electromagnetic spectrum between visible light

and X-rays. The UV spectrum can be broken down into four parts as shown in Table 1.5

. The specific portion of the UV spectrum between 185 and 400 nm (also known as UV-C)

has a strong germicidal effect, with peak effectiveness at 265 nm. At these wavelengths,

UV kills microorganisms by penetrating their cell membranes and damaging the DNA or

RNA, making them unable to reproduce and effectively killing them.

Table 1.5

Four Types of Ultraviolet (UV) Light

Wavelength Range

Description

400–315 nm

UV-A – black light UV

315–280 nm

UV-B – dangerous UV

280–200 nm

UV-C – germicidal UV at 254 nm

200–100 nm

UV-V – vacuum UV

Ultraviolet germicidal irradiation (UVGI) is a sterilization method that uses UV light.

It is used in a variety of applications, such as food, air, and water purification.

It is effective in destroying the nucleic acids in these organisms so that their DNA

is disrupted by the UV radiation. This removes their reproductive capabilities and

kills them.

The application of UVGI to sterilization has been an accepted practice since the mid-twentieth

century. It has been used primarily in medical sanitation and sterile work facilities.

Figure 1.16

shows the use of UV irradiation in a laboratory. UVGI technology is particularly suited

to the beverage, bottled water, and food processing sectors. The design of these systems

is simple as shown in Fig. 1.17

. UVGI disinfection has many advantages over alternative methods. Unlike chemical

biocides, UVGI does not introduce toxins or residues into the process (which themselves

have to be subsequently removed) and does not alter the chemical composition, taste,

odor, or pH of the product.

Figure 1.16

Ultraviolet irradiation in use in a laboratory.

1

For color version of this figure, the reader is referred to the online version of

this book.

Figure 1.17

The flow-through design of a ultraviolet germicidal irradiation for water purification.

For color version of this figure, the reader is referred to the online version of

this book.

UVGI is employed to sterilize drinking and wastewater, as the holding facilities are

enclosed and can be circulated to ensure a higher exposure to the UV. UV sterilizers

are commonly used in aquarium circulation systems and hot tub circulation systems.

In recent years, UVGI has found renewed application in air sanitization.

Mode of Action: UV photons of different energies have various effects on DNA. The

most important damage to DNA is the formation of pyrimidine dimers, which form between

two adjacent pyrimidine bases—cytosine (C) and/or thymine (T) as shown in Fig. 1.18

. This abnormal link distorts the shape of the DNA double helix and blocks its copying

by the DNA replication or RNA transcription machinery. A block in either of these

important processes would be very dangerous for a cell; as little as one dimer per

cell in fact can be lethal. Dimers are formed in DNA most efficiently by UV-C, less

efficiently by UV-B, and very little by UV-A action. The chemical structural changes

are shown in Fig. 1.19

. UV-A light creates mostly free radicals that lead to indirect DNA damage.

7

Figure 1.18

Ultraviolet cross-linking of adjacent thymine dimers in a DNA/RNA strand.

7

Figure 1.19

Ultraviolet cross-linking structural details of adjacent thymine–cytosine in a DNA/RNA

strand on the left, with thymine–thymine dimerization or cross-linking on the right.

1.2.8

Microwave

Microwave sterilization

8

is primarily a thermal process. The heat is generated as microwaves interact with

polar water molecules and charged ions. The water molecules align rapidly in alternating

the electromagnetic field induced by the microwaves; the friction resulting from the

oscillating molecules generates the heat within food. The temperature achieved is

limited to about that of boiling water, unless the food is being held under pressure.

Because the heat is produced directly in the food, the thermal processing time is

sharply reduced compared to processes applying external heat. The food is not necessarily

cooked because the times are short. For commercial food applications, this is a developing

technology. The microwave sterilization technology developed at Washington State University

uses the combination of 915 MHz microwave and conventional heating to improve heating

uniformity. Commercial systems performing microwave pasteurization and/or sterilization

of foods are currently available in Europe

9

(e.g. TOP's Foods); however, the use of microwaves in the United States to produce

prepackaged shelf-stable foods is pending upon FDA acceptance.

Consumers have been able to use their microwaves to sterilize baby bottles in time

as short as 90 s. One such unit is shown in Fig. 1.20

. Steam from boiling water does the sterilizing.

Figure 1.20

Munchkin® Steam Guard Microwave Sterilizer. For color version of this figure, the

reader is referred to the online version of this book.

Mode of Action: The mechanism of germicidal action is essentially heating. Other possible

nonthermal mechanisms have been proposed. One of these is electroporation, cell membrane

damage and rupture, and direct electromagnetic energy coupling leading to cell lysis

(the destruction of cells by disruption of the bounding membrane, allowing the cell

contents to escape). However, scientific support for these mechanisms is not entirely

convincing.

1.2.9

Infrared

IR heating can be used to inactivate bacteria, spores, yeast, and mold in both liquid

and solid foods. Efficacy of microbial inactivation by IR heating depends on several

parameters including:

•

IR power level

•

Temperature of food sample

•

Peak wavelength of IR radiation

•

Bandwidth of IR heating source

•

Sample depth

•

Types of microorganisms

•

Moisture content

•

Types of food materials.

Inactivation mechanism by IR heating may include DNA damage in addition to thermal

effect. Thermal inactivation can damage DNA, RNA, ribosome, cell envelope, and proteins

in microbial cells.

1.2.10

How Does Irradiation Destroy Bacteria?

Radiation breaks the DNA or damages other critical molecules in bacteria, either killing

them or preventing them from reproducing. Irradiation is a process that employs ionizing

energy. Radiation energy ionizes a very small number of the molecules within the food

product and any bacteria within the food product. When a molecule is ionized, it effectively

breaks. If a DNA molecule of a bacterium is ionized, it is damaged or destroyed, preventing

the bacteria from being able to reproduce.

If a water molecule within a bacterium cell is ionized, it can form peroxide and act

as a disinfectant within the bacterium itself. This is covered later in this chapter.

These molecular level changes destroy the bacteria by preventing their reproduction.

Only a very small fraction of the molecules within a living organism, such as a bacterium,

need to be damaged to have this effect. Because only a small fraction of food product

molecules are ionized, minimal adverse effects, such as changes in taste, occur.

1.2.11

Doses of Radiation Required

Radiation dose is the quantity of radiation energy absorbed by the food as it passes

through the radiation field during processing. International health and safety authorities

have endorsed the safety of irradiation for all foods up to a dose level of 10,000 Gy

(10 kGy). The bactericidal efficacy of a given dose of irradiation depends on the

following

10

:

•

The kind and species of the organism (a few are listed in Table 1.6

).

Table 1.6

Approximate Killing Doses of Ionizing Radiations in Kilograys (kGy)

10

Organism

Approximate Lethal Dose (kGy)

Insects

0.22–0.93

Viruses

10–40

Yeasts (fermentative)

4–9

Yeasts (film)

3.7–18

Molds (with spores)

1.3–11

Bacteria

Mycobacterium tuberculosis

1.4

Staphylococcus aureus

1.4–7.0

Corynebacterium diphtheriae

4.2

Salmonella species

3.7–4.8

Escherichia coli

1.0–2.3

Pseudomonas aeruginosa

1.6–2.3

Pseudomonas fluorescens

1.2–2.3

Enterobacter aerogenes

1.4–1.8

Lactobacillus spp.

0.23–0.38

Streptococcus faecalis

1.7–8.8

Leuconostoc dextranicum

0.9

Sarcina lutea

3.7

Bacterial spores

Bacillus subtilis

12–18

Bacillus coagulans

10

Clostridium botulinum (A)

19–37

Clostridium botulinum (E)

15–18

Clostridium perfringens

3.1

Putrefactive anaerobe 3679

23.50

Bacillus stearothermophilus

10–17

•

The numbers of organisms (or spores) originally present. The more organisms there

are, the less effective a given dose will be.

•

The composition of the food. Some constituents may be protective. Compounds that combine

with the SH groups would be sensitizing.

•

The presence or absence of oxygen. The effect of free oxygen varies with the organism,

ranging from no effect to sensitization of the organism. Undesirable “side reactions”

are likely to be intensified in the presence of oxygen and to be less frequent in

a vacuum.

•

The physical state of the food during irradiation. Both moisture content and temperature

affect different organisms in different ways.

•

The condition of the organisms. Age, temperature of growth and sporulation, and state

(vegetative or spore) may affect the sensitivity of the organisms.

1.2.12

Dosimetry

The success of radiation processing of food depends to a large extent on the ability

of the irradiation processor:

•

To measure the absorbed dose delivered to the food product (through reliable dosimetry)

•

To determine the dose distribution patterns in the product package (through process

qualification procedures)

•

To control the routine radiation process (through process control procedures).

This subject is well documented in the literature and will not be discussed further

here.

11

1.3

Medical Sterilization

Until the latter half of the nineteenth century patients undergoing even the most

routine operations were at very high risk of infection because surgery was not performed

under sterile conditions. The operating room, the surgeon's hands, and the surgical

instruments were laden with microbes, which caused high levels of infection and mortality.

At the time bad or contaminated air was believed to be the cause of infection. It

was not until French scientist Louis Pasteur demonstrated that invisible microbes

caused disease, that elimination of them in medical facilities was recognized by numerous

doctors.

Ignaz Philipp Semmelweis was a Hungarian physician now known as an early pioneer of

antiseptic procedures. Described as the “savior of mothers,” Semmelweis discovered

that the incidence of puerperal fever could be drastically cut by the use of hand

disinfection in obstetrical clinics. Puerperal fever, also known as childbed fever,

is a bacterial infection contracted by women during childbirth or miscarriage. It

can develop into puerperal sepsis, which is a serious form of septicemia. It was often

fatal in mid-nineteenth century hospitals with mortality at 10–35%. Semmelweis proposed

washing with chlorinated lime solutions in 1847. He published a book of his findings:

Etiology, Concept, and Prophylaxis of Childbed Fever.

Heinrich Hermann Robert Koch was a German physician who became famous for isolating

Bacillus anthracis (1877), the Tuberculosis bacillus (1882), and Vibrio cholerae (1883)

and for his development of Koch's postulates, which were four criteria to identify

the causative agent of a particular disease. He is considered one of the founders

of microbiology, inspiring such major figures as Paul Ehrlich and Gerhard Domagk.

Joseph Lister is often considered to be the father of modern surgery, who promoted

the idea of sterile surgery while working at the Glasgow Royal Infirmary. Until Lister's

studies of surgery, most people believed that chemical damage from exposure to bad

air, “miasma,” was responsible for infections in wounds. Hospital wards were occasionally

aired out at midday as a precaution against the spread of infection via miasma. Hands

or a patient's wounds were not washed. While he was a professor of surgery at the

University of Glasgow, Lister read a paper published by the French chemist Louis Pasteur,

which showed that rotting and fermentation could occur under anaerobic conditions

if microorganisms were present. Pasteur suggested three methods to eliminate the microorganisms

responsible for gangrene: filtration, exposure to heat, or exposure to chemical solutions.

Lister confirmed Pasteur's conclusions with his own experiments and decided to use

his findings to develop antiseptic techniques for wounds. Lister successfully introduced

carbolic acid (now known as phenol) to sterilize surgical instruments and to clean

wounds, which led to reducing postoperative infections and made surgery safer for

patients.

Therefore, Lister tested the results of spraying instruments, the surgical incisions,

and dressings with a solution of it. Lister found that carbolic acid solution swabbed

on wounds remarkably reduced the incidence of gangrene. In August 1865, Lister applied

a piece of lint dipped in carbolic acid solution onto the wound of an 11-year-old

boy at Glasgow Infirmary, who had sustained a compound fracture after a cart wheel

had passed over his leg. After 4 days, he renewed the pad and discovered that no infection

had developed, and after a total of 6 weeks, he was amazed to discover that the boy's

bones had fused back together, without the danger of formation or discharge of pus.

At that time, the mortality rate of a compound fracture was about 60%. He instructed

surgeons under his responsibility to wear clean gloves and wash their hands before

and after operations with 5% carbolic acid solutions. Instruments were also washed

in the same solution and assistants sprayed the solution into the air in the operating

theatre.

As the germ theory of disease became more widely accepted, it was realized that infection

could be better avoided by preventing bacteria from getting into wounds in the first

place. This led to the rise of sterile surgery. Some consider Lister “the father of

modern antisepsis.” In 1879, Listerine mouthwash was named after him for his work

in antisepsis. Also named in his honor is the bacterial genus Listeria, typified by

the food-borne pathogen Listeria monocytogenes.

Hospitals and other medical treatment facilities are now concerned about sterilization.

What is sterilization? According to the CDC (Centers for Disease Control and Prevention),

“Sterilization means the use of a physical or chemical procedure to destroy all microbial

life, including highly resistant bacterial endospores.” The processes used to kill

microbiological life can affect the materials that are exposed to these processes.

For example, when food is irradiated it is often packaged in plastic materials. How

does the irradiation process affect the properties of the packaging? When medical

devices and facilities are sterilized those processes may affect the plastics used

in providing medical care. The plastics may be implants, surgical tools and supplies,

or packaging for these items. This book is focused on characterizing and understanding

how materials change when they are irradiated or sterilized.

1.3.1

Sterilization, Disinfection, and Asepsis

Medical sterilization is a much broader field than food irradiation. Three terms are

often used when talking about this subject and they are: sterilization, disinfection,

and asepsis. Sterility and asepsis refer to different conditions. Sterility indicates

the elimination (death) of all viable life forms and their germinative elements such

as eggs, spores and endospores. Sterility is absolute; there is no such thing as an

object being “partially sterile.” Asepsis generally means that only certain types

of life forms have been removed, excluded or neutralized (rendered nonviable), while

the presence of other organisms may be tolerated or even promoted. For example, pasteurization

of food does not kill all microorganisms in the food; it does dramatically reduce

the number of microorganisms, with the intent that the pasteurized material is stored

in conditions that will maintain that low number, such as refrigeration. Disinfection

refers to a process whereby many or all pathogenic microorganisms are neutralized

or removed. Unlike sterilization, disinfection can be achieved at varying levels as

defined by the CDC:

•

High-level disinfectants are chemical sterilants that may be used for a shorter exposure

period than would be required for sterilization to kill all microorganisms with the

exception of high numbers of bacterial spores.

•

Intermediate-level disinfectants will kill mycobacteria (causes of tuberculosis and

leprosy), vegetative bacteria, most viruses (such as poliovirus), and most fungi but

do not kill all bacterial spores.

•

Low-level disinfectants kill most vegetative bacteria, some fungi, and some viruses

such as Staphylococcus species, Pseudomonas species, Salmonella species, HIV virus,

herpes simplex virus, hepatitis B, hepatitis C, and many common cold viruses.

There are hundreds of items that are routinely sterilized or disinfected. In terms

of health care/medical items they are often classified by Spaulding's Classification:

critical, semi-critical, and noncritical, as shown in Table 1.7

.

Table 1.7

Spaulding's Classification

Classification

Definition

Level of Processing Required

Critical equipment/device

Equipment/device that enters sterile tissues, including the vascular system

Cleaning followed by sterilization

Semi-critical equipment/device

Equipment/device that comes in contact with nonintact skin or mucous membranes but

do not penetrate them

Cleaning followed by high-level disinfection as minimum; sterilization if preferred

Noncritical equipment/device

Equipment/device that touches only intact skin and not mucous membranes or does not

directly touch the client/patient/resident

Cleaning followed by low-level disinfection. In some cases, cleaning alone is acceptable

Disinfection and sterilization are both decontamination processes. While disinfection

is the process of eliminating or reducing harmful microorganisms from inanimate objects

and surfaces, sterilization is the process of killing all microorganisms. Sterilization

also destroys the spores of various organisms present on surfaces, in liquids, in

medication, or in compounds such as biological culture media. Such “extreme” forms

of decontamination are needed during critical times like surgery, or in environments

like industrial, laboratory or hospital. It is more practical to use disinfection

in everyday life.

Disinfection is usually carried out using chemicals, often solutions, but also vapors

and gases. When chemicals are used to destroy all forms of microbiologic life, they

can be called chemical sterilants. These same germicides used for shorter exposure

periods also can be part of the disinfection process (i.e. high-level disinfection).

Sterilization falls into the following three basic categories of which there are several

options in each category:

1.

High temperature/pressure sterilization (autoclave)

2.

Chemical sterilization

3.

Radiation sterilization.

Each of these and several less common methods are discussed in later sections.

1.3.2

Thermal Methods of Sterilization

Heat is one of the oldest and cheapest ways to sterilize food, tools, equipment, etc.

There are several basic ways to utilize heat and these are described in the following

sections.

1.3.2.1

Steam Sterilization/Autoclave

The steam autoclave is the oldest, safest, most widely used and most cost-effective

method of sterilization in the medical equipment industry. Steam is generated in a

pressure chamber so that it reaches a temperature 121–148 °C (250–300 °F) at 15 p.s.i.

The time items are kept exposed is dependent on the temperature and size of load and

usually ranges from 10 to 60 min. There are two main types of steam autoclaves, gravity

displacement and pre-vacuum cycle.

Gravity displacement autoclaves remove air from the chamber by gravity displacement

as steam-entering chamber near the top exerts pressure on air forcing it out of the

bottom as shown in Fig. 1.21

. A photo of an industrial-size steam autoclave is shown in Fig. 1.22

.

Figure 1.21

Diagram of a gravity displacement steam autoclave (courtesy of Pearson Education).

For color version of this figure, the reader is referred to the online version of

this book.

Figure 1.22

Picture of a large industrial size autoclave. For color version of this figure, the

reader is referred to the online version of this book.

The high-speed pre-vacuum sterilizers are similar to the gravity displacement sterilizers

except they are fitted with a vacuum pump (or ejector) to ensure air removal from

the sterilizing chamber and load before the steam is admitted. The advantage of using

a vacuum pump is that there is nearly instantaneous steam penetration even into porous

loads.

Table 1.8

summarizes the processing parameters for each cycle of the two types of steam autoclaves:

Table 1.8

Operating Parameters for Steam Autoclaves

Configuration

Temperature

Time

Gravity displacement

121–123 °C (250–254 °F)

15–30 min

132–135 °C (270–272 °F)

10–25 min

Pre-vacuum

132–135 °C (270–272 °F)

3–4 min

Like all sterilization processes, steam sterilization may have some damaging effects

on some materials. At constant temperatures, sterilization times vary depending on

the type of item (e.g. metal versus rubber, plastic, items with lumens), whether the

item is wrapped or unwrapped, and the sterilizer type.

Mode of Action: Moist heat destroys microorganisms by the irreversible coagulation

and denaturation of enzymes and structural proteins. In support of this fact, it has

been found that the presence of moisture significantly affects the coagulation temperature

of proteins and the temperature at which microorganisms are destroyed.

Uses: Steam sterilization is used whenever possible on all critical and semi-critical

items that are heat and moisture resistant (e.g. steam sterilizable respiratory therapy

and anesthesia equipment), even when not essential to prevent pathogen transmission.

Steam sterilizers also are used in health care facilities to decontaminate microbiological

waste and sharps containers but additional exposure time is required in the gravity

displacement sterilizer for these items. Steam sterilizers are common in dental facilities.

Advantages:

•

Nontoxic to patient, staff, environment

•

Cycle easy to control and monitor

•

Rapidly microbicidal

•

Least affected by organic/inorganic soils among sterilization processes listed

•

Rapid cycle time

•

Penetrates medical packing, device lumens.

Disadvantages:

•

Deleterious for heat-sensitive instruments

•

Microsurgical instruments damaged by repeated exposure can corrode surgical alloys

and cutting edges

•

Development of pitting and dulling of the cutting edges after multiple steam sterilization

cycles

•

May leave instruments wet, causing them to rust

•

Potential for burns.

1.3.2.2

Flash Sterilization

Flash sterilization is often called immediate-use steam sterilization.

12

“Immediate use” is broadly defined as the shortest possible time between a sterilized

item's removal from the sterilizer and its aseptic transfer to the sterile field.

It is used for sterilizing cleaned patient-care items that cannot be packaged, sterilized,

and stored before use. It also is used when there is insufficient time to sterilize

an item by the preferred package method. “Flash” steam sterilization was originally

defined by Underwood and Perkins as sterilization of an unwrapped object at 132°C

for 3 min at 27–28 lbs of pressure in a gravity displacement sterilizer.

Often flash sterilization equipment is located very close to operating rooms to handle

urgent needs. However, care must be taken to avoid burns to both the medical staff

and the patient. Burns may be prevented by either air cooling the instruments or immersion

in a sterile liquid such as saline.

Uses: Flash sterilization should not be used for reasons of convenience. It is not

recommended for implantable devices except where unavoidable.

1.3.2.3

Dry Heat Sterilization

Dry heat is effective at inactivating microorganisms, but in general, the temperatures

required are higher than is required for steam sterilization to achieve an equivalent

level of germicidal action. This method should be used only for materials that might

be damaged by moist heat or that are impenetrable to moist heat (e.g. powders, petroleum

products, sharp instruments).

There are two types of dry heat sterilizers: the static-air type and the forced-air

type. The differences are like two types of ovens common in everyday home kitchens.

The static type is like a conventional oven and the forced-air type is like a convection

oven. The static-air type has heating coils in the bottom of the unit cause the hot

air to rise inside the chamber via convection. This type of dry heat sterilizer is

much slower in heating, requires longer time to reach sterilizing temperature, and

is less uniform in temperature control throughout the chamber than is the forced-air

type. The forced-air or mechanical convection sterilizer is equipped with a motor-driven

blower that circulates heated air throughout the chamber at a high velocity, permitting

a more rapid transfer of energy from the air to the instruments.

Common time–temperature relationships for sterilization with hot air sterilizers are:

•

170 °C (340 °F) for 60 min

•

160 °C (320 °F) for 120 min

•

150 °C (300 °F) for 150 min.

The advantages for dry heat include:

•

It is nontoxic

•

Does not harm the environment

•

Easy to install

•

Relatively low operating costs

•

It penetrates materials

•

It is noncorrosive for metal.

The main disadvantage is time. Dry heat penetration and microbial killing is time

consuming by this method. In addition, the high temperatures are not suitable for

most materials.

Mode of Action: The primary lethal process is considered to be oxidation of cell constituents.

1.3.2.4

Glass Bead Sterilizer

Glass bead “sterilization” uses small glass beads (1.2–1.5 mm diameter) and high temperature

(217–232 °C) for brief exposure times (e.g. 45 s) to inactivate microorganisms. They

are typically used on metal surgical instruments as shown in Fig. 1.23

. These devices have been used for several years in the dental profession. FDA believes

there is a risk of infection with this device because of potential failure to sterilize

dental instruments and their use should be discontinued until the device has received

FDA clearance.

Figure 1.23

Picture of a glass bead sterilizer (photo courtesy of Cellpoint Scientific Inc.).

For color version of this figure, the reader is referred to the online version of

this book.

1.3.2.5

Microwave

Microwaves are used in medicine for disinfection of soft contact lenses, dental instruments,

dentures, milk, and urinary catheters for intermittent self-catheterization. However,

microwaves must only be used with products that are compatible (e.g. do not melt).

Microwaves are radio frequency waves, which are usually used at a frequency of 2450 MHz.

The microwaves produce friction of water molecules in an alternating electrical field.

The intermolecular friction derived from the vibrations generates heat and some authors

believe that the effect of microwaves depends on the heat produced while others postulate

a nonthermal lethal effect. The initial reports showed microwaves to be an effective

microbicide. The microwaves produced by a “home-type” microwave oven (2.45 GHz) completely

inactivate bacterial cultures, mycobacteria, viruses, and Geobacillus stearothermophilus

spores within 60 s to 5 min depending on the organism. Another study confirmed these

results but also found that higher power microwaves in the presence of water may be

needed for sterilization. Microwaves used for sterilization of medical devices have

not been FDA cleared.

1.3.2.6

IR Radiation

An IR radiation prototype sterilizer was investigated and found to destroy Bacillus

atrophaeus spores. IR heating can be effectively used for enzyme inactivation. IR

heating can be used to inactivate bacteria, spores, yeast, and mold in both liquid

and solid foods. Efficacy of microbial inactivation by IR heating depends on the following

parameters: IR power level, temperature of food sample, peak wavelength, bandwidth

of IR heating source, sample depth, types of microorganisms, moisture content, and

types of food materials.

13

Some of the possible advantages of IR technology include short cycle time, low energy

consumption, no cycle residuals, and no toxicological or environmental effects. This

may provide an alternative technology for sterilization of selected heat-resistant

instruments but there are no FDA-cleared systems for use in health care facilities.

1.3.3

Chemical Disinfectants – Liquids

There are many liquid chemical disinfectants available.14., 15. Some of these may

be used in vapor form and that approach is discussed in the next section. All disinfectants

act by harming microorganisms in some manner. The different disinfectants have different

mechanisms of action. These mechanisms of harm include:

•

Protein denaturation

•

Membrane disruption

•

Nucleic acid damage

•

Inhibition of metabolism.

Protein denaturation

It is commonly defined as any noncovalent change in the structure of a protein. This

change may alter the secondary, tertiary, or quaternary structure of the molecules.

For those proteins that are enzymes, denaturation can be defined as the loss of enough

structure to render the enzyme inactive, see Fig. 1.24

.

Figure 1.24

Denaturation of a protein can change its shape, which can destroy its function.

Membrane disruption

The bacterial cytoplasmic membrane is composed of a phospholipid bilayer. It has all

the general functions of a cell membrane such as acting as a permeability barrier

for most molecules and serving as the location for the transport of molecules into

the cell. Membrane disruption by chemical disinfectants is the breakdown of that membrane,

which means loss of the permeability barrier and death to the microorganism.

Nucleic acid damage

DNA damage affects the primary structure of the double helix; that is, the bases themselves

are chemically modified. These modifications can in turn disrupt the molecules' regular

helical structure by introducing nonnative chemical bonds or bulky adducts that do

not fit in the standard double helix:

•

Oxidation of bases and generation of DNA strand interruptions from reactive oxygen

species

•

Alkylation of bases (usually methylation)

•

Hydrolysis of bases, such as deamination, depurination, and depyrimidination.

Inhibition of metabolism

An enzyme inhibitor is a molecule that binds to enzymes and decreases their activity.

Since blocking an enzyme's activity can kill a pathogen or correct a metabolic imbalance.

Many liquid chemical sterilants are discussed in the following sections. Generally

for each sterilant, a chemical description or structure is provided. The mode of action

is noted and described. Typical uses of the sterilants are listed as are the advantages

and disadvantages to it use are summarized.

1.3.3.1

Alcohol

In the health care setting, “alcohol” refers to two water-soluble chemical compounds—ethyl

alcohol and isopropyl alcohol. FDA has not cleared any liquid chemical sterilant or

high-level disinfectant with alcohol as the main active ingredient. These alcohols

are rapidly bactericidal against vegetative forms of bacteria, fungicidal (an agent

that destroys fungi), and virucidal (capable of neutralizing or destroying a virus).

Alcohols do not destroy bacterial spores. Their cidal activity drops sharply when

diluted below 50% concentration, and the optimum bactericidal concentration is 60–90%

solution in water (volume/volume).

Mode of Action: The most feasible explanation for the antimicrobial action of alcohol

is denaturation of proteins. Protein shape is critical to performance of the protein.

That shape is maintained by intermolecular forces such as hydrogen bonding (see Section

2.8.1). An example is shown in Fig. 1.25

which shows the hydrogen bonding between two amino acids.

Figure 1.25

Denaturation of hydrogen bonding between two amino acids (aspartic acid, tyrosine)

in a protein by ethanol.

16

Microbiocidal Activity: Methyl alcohol (methanol) has the weakest bactericidal action

of the alcohols and thus seldom is used in health care. The bactericidal activity

of various concentrations of ethyl alcohol (ethanol) and isopropanol ranges from 10 s

to hours depending on the microorganism.

Uses: A 70% alcohol solution is used as a disinfectant on the skin. This concentration

of alcohol is able to penetrate the bacterial cell wall and denature the proteins

and enzymes inside of the cell. A 95% alcohol solution merely coagulates the protein

on the outside of the cell wall and prevents any alcohol from entering the cell. Alcohols

are not recommended for sterilizing medical and surgical materials principally because

they lack sporicidal action and they cannot penetrate protein-rich materials. Alcohols

have been used effectively to disinfect oral and rectal thermometers, hospital pagers,

scissors, and stethoscopes. Alcohol towelettes have been used to disinfect small surfaces

such as rubber stoppers of multiple-dose medication vials or vaccine bottles. Furthermore,

alcohol occasionally is used to disinfect external surfaces of equipment (e.g. stethoscopes,

ventilators, and manual ventilation bags), Cardiopulmonary resuscitation (CPR) manikins,

ultrasound instruments or medication preparation areas. Alcohols may damage coatings,

plastics, and elastomers.

1.3.3.2

Chlorine and Chlorine Compounds

Chlorine's disinfecting effects are well known as it has been used to disinfect drinking

water for many years. Many chlorine compounds release chlorine and are used in the

health care setting. The advantage of these compounds over the hypochlorites is that

they retain chlorine longer and so exert a more prolonged bactericidal effect. Some

of these are discussed in the next sections.

1.3.3.2.1

Hypochlorites

Hypochlorites, the most widely used of the chlorine disinfectants, are available as

liquid (household bleach, sodium hypochlorite) or solid (common pool chlorine, calcium

hypochlorite). The hypochlorite ion, also known as chlorate (I) anion, is ClO−. Household

bleach is an aqueous solution of 5.25%–6.15% sodium hypochlorite.

Hypochlorites have a broad-spectrum of antimicrobial activity. They do not leave toxic

residues, are unaffected by water hardness, are inexpensive and fast acting. They

remove dried or fixed organisms and biofilms from surfaces and have a low incidence

of serious toxicity.

One danger is the release of toxic chlorine gas when mixed with ammonia or acid (e.g.

household cleaning agents). The microbicidal activity of chlorine is attributed largely

to undissociated hypochlorous acid (HOCl). The dissociation of HOCl to the less microbicidal

form (hypochlorite ion OCl−) depends on pH. The disinfecting efficacy of chlorine

decreases with an increase in pH that parallels the conversion of undissociated HOCl

to OCl−.

1.3.3.2.2

Chlorine dioxide

Chlorine dioxide (CD, ClO2) is greenish yellow and is an oxidizing agent with a chlorine-like

odor. ClO2 is effective against bacteria, yeasts, molds, and viruses. The rapid sterilizing

activity of ClO2 is present at ambient temperature and at relatively low gas concentration,

1–30 mg/l.

Traditionally, chlorine dioxide for disinfection applications is made where it is

to be used by one of three methods using sodium chlorite or the sodium chlorite–hypochlorite

method:

2

NaClO

2

+

2

HCl

+

NaOCl

→

2

ClO

2

+

3

NaCl

+

H

2

O

or the sodium chlorite–hydrochloric acid method:

5

NaClO

2

+

4

HCl

→

5

NaCl

+

4

ClO

2

+

2

H

2

O

Mode of Action: Chlorine dioxide acts as an oxidizing agent and reacts with several

cellular constituents, including the cell membrane of microbes. The potency of chlorine

dioxide is attributable to the simultaneous, oxidative attack on many proteins thereby

preventing the cells from mutating to a resistant form.

Uses: Drinking water, poultry process water, swimming pools, and mouthwash preparations.

It is used to sanitize fruit and vegetables as well as equipment for food and beverage

processing. It is used in the life sciences industry to decontaminate animal research

facilities. It is also employed in the health care industries to decontaminate rooms,

pass-throughs, isolators, and also as a sterilant for product and component sterilization.

1.3.3.2.3

Sodium dichloroisocyanurate

Sodium dichloroisocyanurate is used as a disinfectant in water. Its structure is shown

in Fig. 1.26

. It is considered to be a halogen donor, a chemical that releases active chlorine.

After release, the halogen reaction is similar to that of chlorine or bromine from

other sources. Chlorine donor chemicals do not release the active chlorine all at

once, but make it slowly available.

Figure 1.26

Chemical structure of sodium dichloroisocyanurate.

1.3.3.2.4

Chloramine-T

Chloramine-T, the structure of which is shown in Fig. 1.27

, is available in tablet or powder form and has to be dissolved before use. It is

sprayed on a surface and allowed to stand for at least 15 min before being wiped off

or allowed to dry.

Figure 1.27

Chemical structure of chloramine-T (N-chloro 4-methylbenzenesulfonamide, sodium salt).