- Record: found

- Abstract: found

- Article: found

Study on Tribological Properties and Mechanisms of Different Morphology WS 2 as Lubricant Additives

Read this article at

Abstract

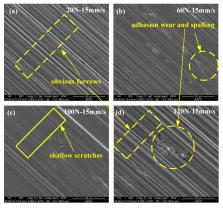

In the present work, the relationship curve of the coefficient of friction (COF) with varying loads of different morphology WS 2 lubricating additives in the friction process at various sliding speeds was studied. On this basis, wear marks and elements on the wear surfaces after friction were analyzed, and then the anti-wear and mechanism effects of WS 2 of different forms in the lubrication process were discussed. Meanwhile, the Stribeck curve was used to study the lubrication state of the lubricating oil in the friction process. It was revealed that the COF of lubricating oil containing lamellar WS 2 decreased by 29.35% at optimum condition and the minimum COF was concentrated at around 100 N. The COF of lubricating oil containing spherical WS 2 decreased by 30.24% and the minimum coefficient was concentrated at 120 N. The extreme pressure property of spherical WS 2 was better than that of lamellar WS 2, and the wear resistance of spherical WS 2 was more stable when the load was over 80 N. The different morphology of WS 2 additives can play anti-wear and anti-friction roles within a wide range of sliding speeds.

Related collections

Most cited references34

- Record: found

- Abstract: not found

- Article: not found

Contact and Rubbing of Flat Surfaces

- Record: found

- Abstract: not found

- Article: not found

Roles of nanoparticles in oil lubrication

- Record: found

- Abstract: found

- Article: not found