- Record: found

- Abstract: found

- Article: found

Co-immobilization of amine dehydrogenase and glucose dehydrogenase for the biosynthesis of ( S)-2-aminobutan-1-ol in continuous flow

Read this article at

Abstract

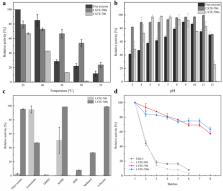

Reductive amination by amine dehydrogenases is a green and sustainable process that produces only water as the by-product. In this study, a continuous flow process was designed utilizing a packed bed reactor filled with co-immobilized amine dehydrogenase wh84 and glucose dehydrogenase for the highly efficient biocatalytic synthesis of chiral amino alcohols. The immobilized amine dehydrogenase wh84 exhibited better thermo-, pH and solvent stability with high activity recovery. ( S)-2-aminobutan-1-ol was produced in up to 99% conversion and 99% ee in the continuous flow processes, and the space-time yields were up to 124.5 g L -1 d -1. The continuous reactions were also extended to 48 h affording up to 91.8% average conversions. This study showcased the important potential to sustainable production of chiral amino alcohols in continuous flow processes.

Related collections

Most cited references46

- Record: found

- Abstract: not found

- Article: not found