- Record: found

- Abstract: found

- Article: found

Cyclic Deformation Behavior of A Heat-Treated Die-Cast Al-Mg-Si-Based Aluminum Alloy

Read this article at

Abstract

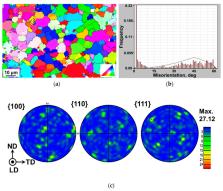

The purpose of this investigation was to study the low-cycle fatigue (LCF) behavior of a newly developed high-pressure die-cast (HPDC) Al-5.5Mg-2.5Si-0.6Mn-0.2Fe (AlMgSiMnFe) alloy. The effect of heat-treatment in comparison with its as-cast counterpart was also identified. The layered (α-Al + Mg 2Si) eutectic structure plus a small amount of Al 8(Fe,Mn) 2Si phase in the as-cast condition became an in-situ Mg 2Si particulate-reinforced aluminum composite with spherical Mg 2Si particles uniformly distributed in the α-Al matrix after heat treatment. Due to the spheroidization of intermetallic phases including both Mg 2Si and Al 8(Fe,Mn) 2Si, the ductility and hardening capacity increased while the yield stress (YS) and ultimate tensile strength (UTS) decreased. Portevin–Le Chatelier effect (or serrated flow) was observed in both tensile stress–strain curves and initial hysteresis loops during cyclic deformation because of dynamic strain aging caused by strong dislocation–precipitate interactions. The alloy exhibited cyclic hardening in both as-cast and heat-treated conditions when the applied total strain amplitude was above 0.4%, below which cyclic stabilization was sustained. The heat-treated alloy displayed a larger plastic strain amplitude and a lower stress amplitude at a given total strain amplitude, demonstrating a superior fatigue resistance in the LCF regime. A simple equation based on the stress amplitude of the first and mid-life cycles ( , ) was proposed to characterize the degree of cyclic hardening/softening ( D): where the positive sign “+” represents cyclic hardening and the negative sign “−“ reflects cyclic softening.

Related collections

Most cited references70

- Record: found

- Abstract: found

- Article: not found

Opportunities and challenges for a sustainable energy future.

- Record: found

- Abstract: found

- Article: not found

Impacts and mitigation of excess diesel-related NOx emissions in 11 major vehicle markets

- Record: found

- Abstract: not found

- Article: not found