- Record: found

- Abstract: found

- Article: found

Sugar glass fugitive ink loaded with calcium chloride for the rapid casting of alginate scaffold designs

Read this article at

Abstract

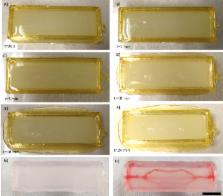

Alginate-based hydrogels are widely used for the development of biomedical scaffolds in regenerative medicine. The use of sugar glass as a sacrificial template for fluidic channels fabrication within alginate scaffolds remains a challenge because of the premature dissolution of sugar by the water contained in the alginate as well as the relatively slow internal gelation rate of the alginate. Here, a new and simple method, based on a sugar glass fugitive ink loaded with calcium chloride to build sacrificial molds, is presented. We used a dual calcium cross-linking process by adding this highly soluble calcium source in the printed sugar, thus allowing the rapid gelation of a thin membrane of alginate around the sugar construct, followed by the addition of calcium carbonate and gluconic acid δ-lactone to complete the process. This innovative technique results in the rapid formation of "on-demand" alginate hydrogel with complex fluidic channels that could be used in biomedical applications such as highly vascularized scaffolds promoting pathways for nutrients and oxygen to the cells.

Related collections

Most cited references13

- Record: found

- Abstract: not found

- Article: not found

Omnidirectional printing of 3D microvascular networks.

- Record: found

- Abstract: not found

- Article: not found

Engineering vascularized tissue.

- Record: found

- Abstract: found

- Article: not found