- Record: found

- Abstract: found

- Article: found

A study on the fabrication of metal microneedle array electrodes for ECG detection based on low melting point Bi–In–Sn alloys

Read this article at

Abstract

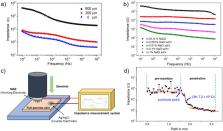

This study describes the fabrication and characteristics of microneedle array electrodes (MAEs) using Bismuth–Indium–Tin (Bi–In–Sn) alloys. The MAEs consist of 57 pyramid-shaped needles measuring 340 μm wide and 800 μm high. The fabrication process involved micromolding the alloys in a vacuum environment. Physical tests demonstrated that Bi–In–Sn MAEs have good mechanical strength, indicating their suitability for successful skin penetration. The electrode–skin interface impedance test confirmed that Bi–In–Sn MAEs successfully penetrated the skin. Impedance measurements revealed the importance of insulating the microneedle electrodes for optimal electrical performance, and a UV-curable Polyurethane Acrylate coating was applied to enhance insulation. Electrocardiogram measurements using the Bi–In–Sn MAEs demonstrated performance comparable to that of traditional Ag/AgCl electrodes, which shows promise for accurate data collection. Overall, the study demonstrates successful, minimally-invasive skin insertion, improved electrical insulation, and potential applications of Bi–In–Sn microneedle array. These findings contribute to advancements in microneedle technology for biomedical applications.

Related collections

Most cited references36

- Record: found

- Abstract: found

- Article: not found

Dissolving microneedles for transdermal drug delivery.

- Record: found

- Abstract: not found

- Article: not found