- Record: found

- Abstract: found

- Article: not found

Influence of tibiofemoral congruency design on the wear of patient-specific unicompartmental knee arthroplasty using finite element analysis

Read this article at

Abstract

Objectives

Unicompartmental knee arthroplasty (UKA) is an alternative to total knee arthroplasty for patients who require treatment of single-compartment osteoarthritis, especially for young patients. To satisfy this requirement, new patient-specific prosthetic designs have been introduced. The patient-specific UKA is designed on the basis of data from preoperative medical images. In general, knee implant design with increased conformity has been developed to provide lower contact stress and reduced wear on the tibial insert compared with flat knee designs. The different tibiofemoral conformity may provide designers the opportunity to address both wear and kinematic design goals simultaneously. The aim of this study was to evaluate wear prediction with respect to tibiofemoral conformity design in patient-specific UKA under gait loading conditions by using a previously validated computational wear method.

Methods

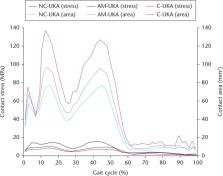

Three designs with different conformities were developed with the same femoral component: a flat design normally used in fixed-bearing UKA, a tibia plateau anatomy mimetic (AM) design, and an increased conforming design. We investigated the kinematics, contact stress, contact area, wear rate, and volumetric wear of the three different tibial insert designs.

Results

Conforming increased design showed a lower contact stress and increased contact area. In addition, increased conformity resulted in a reduction of the wear rate and volumetric wear. However, the increased conformity design showed limited kinematics.

Conclusion

Our results indicated that increased conformity provided improvements in wear but resulted in limited kinematics. Therefore, increased conformity should be avoided in fixed-bearing patient-specific UKA design. We recommend a flat or plateau AM tibial insert design in patient-specific UKA.

Cite this article: Y-G. Koh, K-M. Park, H-Y. Lee, K-T. Kang. Influence of tibiofemoral congruency design on the wear of patient-specific unicompartmental knee arthroplasty using finite element analysis. Bone Joint Res 2019;8:156–164. DOI: 10.1302/2046-3758.83.BJR-2018-0193.R1.

Related collections

Most cited references55

- Record: found

- Abstract: found

- Article: not found

The movement of the normal tibio-femoral joint.

- Record: found

- Abstract: not found

- Article: not found

The Wear of Metals under Unlubricated Conditions

- Record: found

- Abstract: found

- Article: not found