- Record: found

- Abstract: found

- Article: found

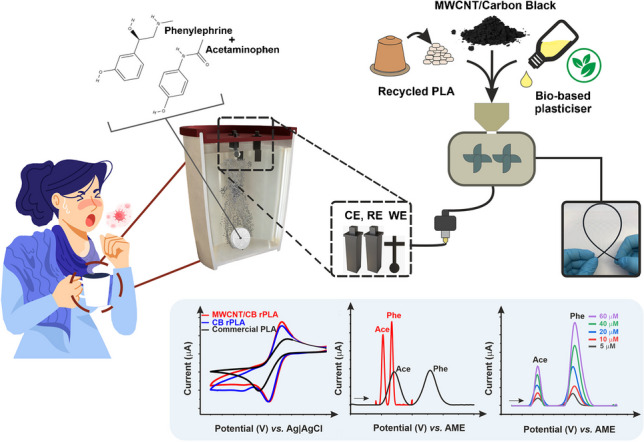

Multi-walled carbon nanotubes/carbon black/rPLA for high-performance conductive additive manufacturing filament and the simultaneous detection of acetaminophen and phenylephrine

Read this article at

Abstract

The combination of multi-walled carbon nanotubes (MWCNT) and carbon black (CB) is presented to produce a high-performance electrically conductive recycled additive manufacturing filament. The filament and subsequent additively manufactured electrodes were characterised by TGA, XPS, Raman, and SEM and showed excellent low-temperature flexibility. The MWCNT/CB filament exhibited an improved electrochemical performance compared to an identical in-house produced bespoke filament using only CB. A heterogeneous electrochemical rate constant, \documentclass[12pt]{minimal} \usepackage{amsmath} \usepackage{wasysym} \usepackage{amsfonts} \usepackage{amssymb} \usepackage{amsbsy} \usepackage{mathrsfs} \usepackage{upgreek} \setlength{\oddsidemargin}{-69pt} \begin{document}$${k}_{obs}^0$$\end{document} of 1.71 (± 0.19) × 10 −3 cm s −1 was obtained, showing an almost six times improvement over the commonly used commercial conductive CB/PLA. The filament was successfully tested for the simultaneous determination of acetaminophen and phenylephrine, producing linear ranges of 5–60 and 5–200 μM, sensitivities of 0.05 μA μM −1 and 0.14 μA μM −1, and limits of detection of 0.04 μM and 0.38 μM, respectively. A print-at-home device is presented where a removable lid comprised of rPLA can be placed onto a drinking vessel and the working, counter, and reference components made from our bespoke MWCNT/CB filament. The print-at-home device was successfully used to determine both compounds within real pharmaceutical products, with recoveries between 87 and 120% over a range of three real samples. This work paves the way for fabricating new highly conductive filaments using a combination of carbon materials with different morphologies and physicochemical properties and their application to produce additively manufactured electrodes with greatly improved electrochemical performance.

Related collections

Most cited references41

- Record: found

- Abstract: not found

- Article: not found

Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects

- Record: found

- Abstract: found

- Article: not found

Raman spectroscopy as a versatile tool for studying the properties of graphene

- Record: found

- Abstract: not found

- Article: not found